Electric conveyors – clean and safe

The Conveyor 22 Linear Conveyor is the cleanest, most reliable and cost-efficient on the market. Our customers come from a broad array of industries including metal, mining, automotive, automation, vision, furniture, recycle, food and pharmaceutical companies.

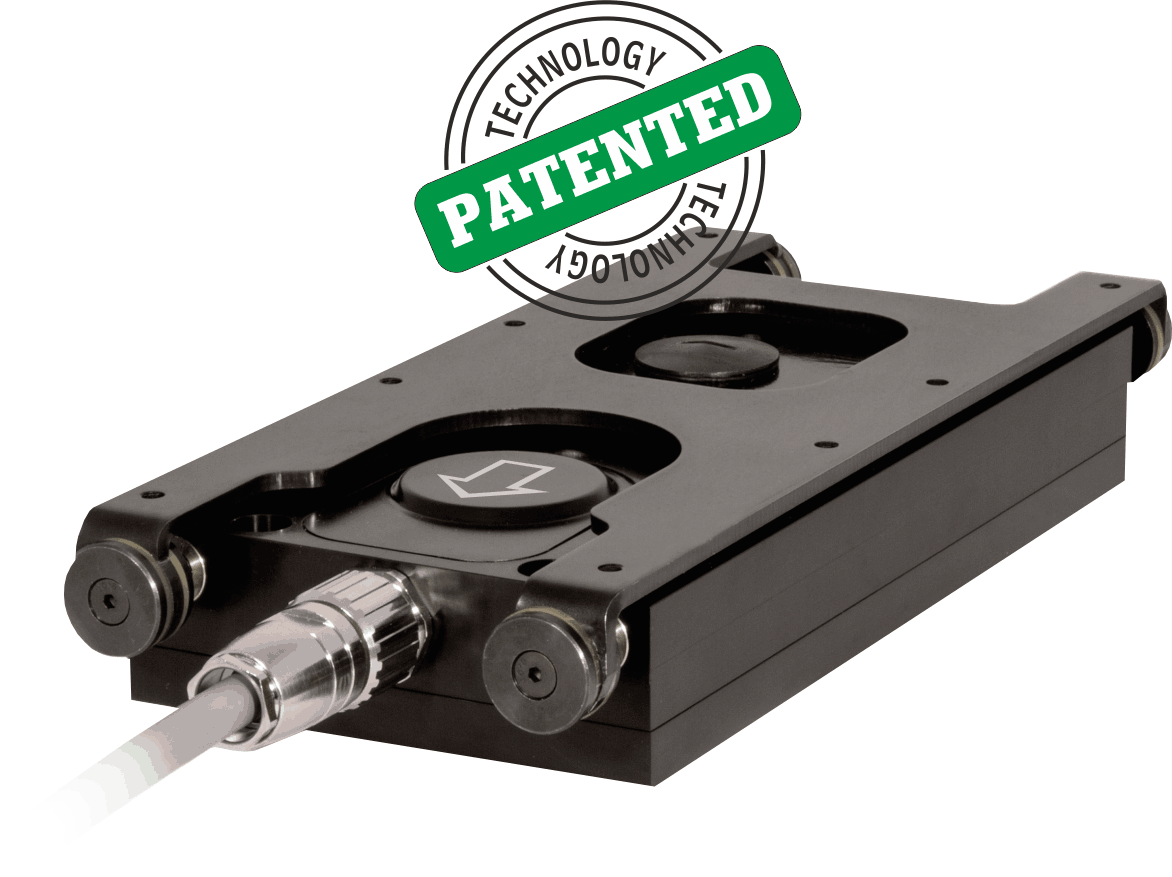

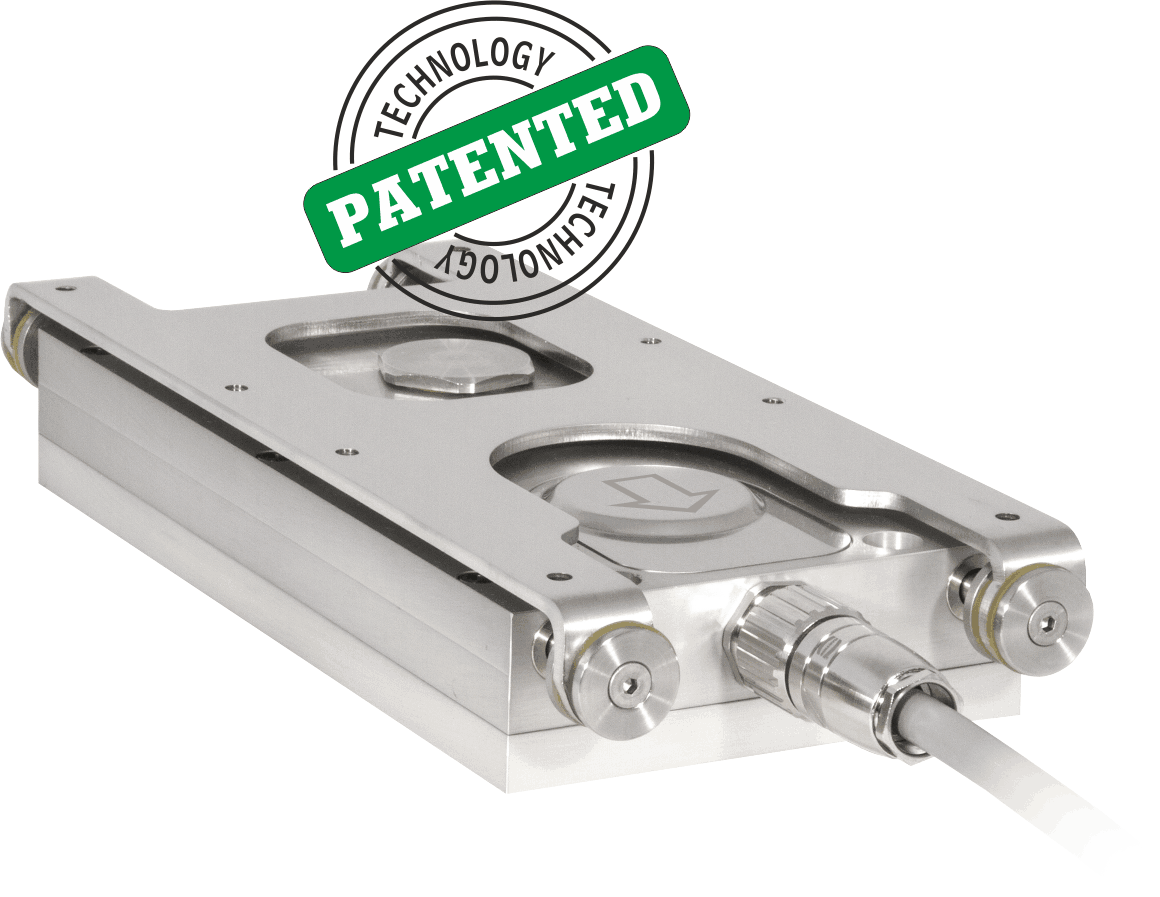

Our patented technology optimizes manufacturing productivity and simplifies automation process, contributing to a sustainable energy system and a friendly working environment.

Our business areas

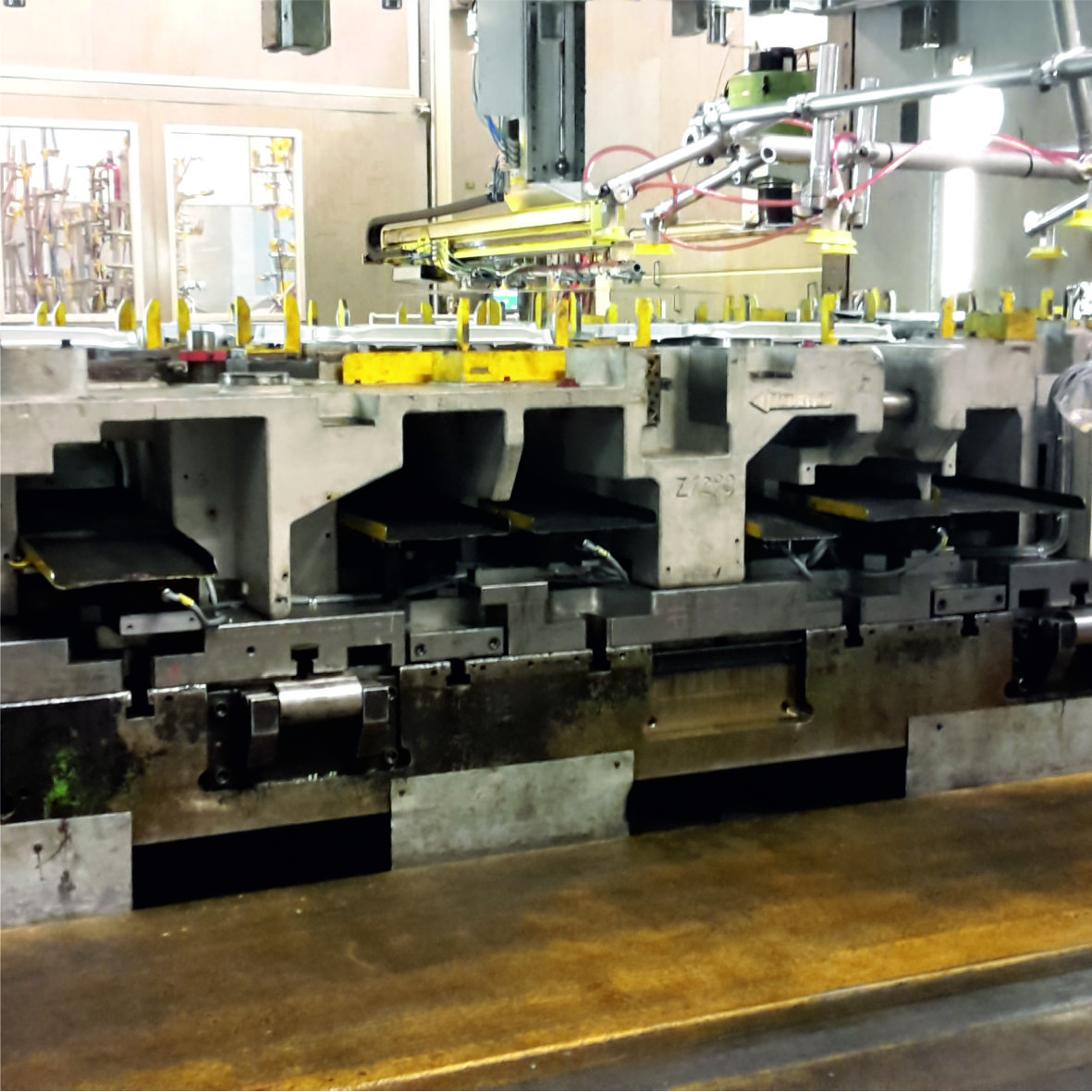

Stamping & Manufacturing

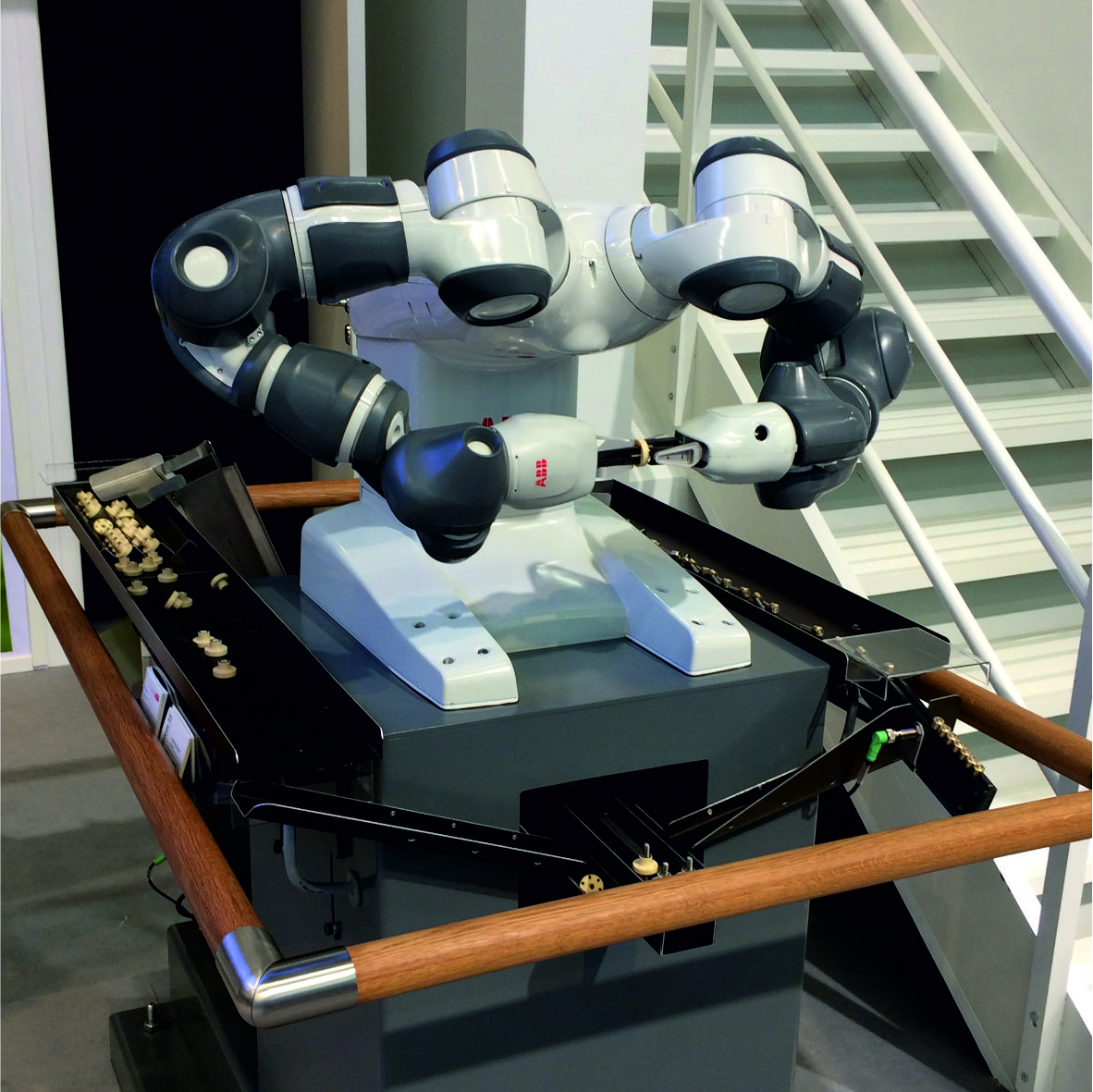

Automation & Robotics